-

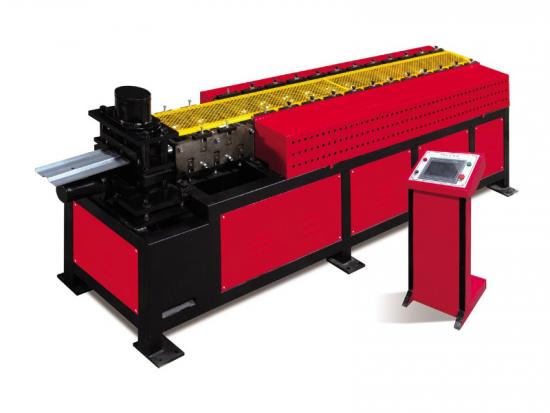

TDF Fire Damper Frame Production Line

Fire damper machine consists of frame production line,positive pressure air supply outlet production line,blades forming machine,supporting bar forming machine,spring forming machine,riveting platform and so on.Hot Tags : VCD frame production line VCD frame forming machine Fire damper machinery VCD damper frame roll forming machine

Read More -

Damper Blade Roll Forming Machine

The blade forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : Blade forming machine Blades forming machine VCD damper blade roll forming machine HVAC damper blade rolling forming machine

Read More -

Baffler forming machine for fire damper machine

The baffler forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : VCD machinery Fire damper machines

Read More -

HVAC Damper Spring Leaf Roll Forming Machine

The spring forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : Spring Forming Machine Spring rolling machine

Read More -

HVAC Damper Rivet Table

Fire damper riveting platform consist of frame riveting(four rivets),TDF corner riveter(four rivets),supporting bar riveting(two rivets) and baffler rivets(single rivet).Hot Tags : Riveting platform Volume control damper machinery Volume control damper machines

Read More -

Duct Manufacturing Auto Line VIII

Air duct production line Ⅷ is a new type of air duct automatic production line of our company. The U-shaped structure not only saves the production site, but also reduces the delivery time of raw materials. The production efficiency is high (about 20-23 seconds per piece). The department fully automatically realizes the fixed size cutting, beading, automatic cutting ,the notching, single hem forming, pittsburgh forming, TDF flange and the angle iron flange ,automatically forming and bent into ”L“, ”U“, ”口“ shaped duct. Equipped with punching support air, TDF flange hole is optional. Pittsburgh is formed before bending the short side of the large size duct. It has the advantages of high automation, high efficiency, labor saving and material saving.Hot Tags : Duct manufacturing auto line Fully-automatic duct making line HVAC duct machinery line Automatic duct line Rectangular duct forming machine HVAC machine

Read More -

Duct Manufacturing Auto Line VII

HVAC duct line Ⅶ ,with U-shaped structure not only saves the production site, but also reduces the delivery time of raw materials. The production efficiency is high (about 20-23 seconds per piece). The department fully automatically realizes the fixed size cutting, beading, automatic cutting ,the notching, single hem folding, pittsburgh forming, TDF flange and the angle iron flange ,automatically forming and bent into ”L“, ”U“, ”口“ shaped duct. Equipped with punching support air, TDF flange hole is optional. Pittsburgh is formed before bending the short side of the large size duct.C+S flange is optional.It has the advantages of high automation, high efficiency, labor saving and material saving.Hot Tags : HVAC machinery line HVAC machinery HVAC auto duct line machine HVAC fabricate duct complete line

Read More -

Duct Manufacture Super Auto-Line l

The uncoiling and leveling production line is used for various roll bending processes. After uncoiling, leveling, and cutting, flat sheets of the required width and length can be obtained. The production line consists of a feeding rack, uncoiler, leveler, conveyor, guide device, length fixing device, plastic cover plate device, shearer, and conveyor table.Hot Tags : Cut to length line blanking line Metal cutter Decoiler and straight for material Steel coil cutting machine Coil cut to length line

Read More -

Duct Manufacturing Auto Line lll

HVAC duct fabrication machine Ⅲ features in high auomation,high efficiency and saving materials,which is very suitable for mass production of square ducts. Autoline - III consists of a metal feeding frame, leveling and grooving equipment, hydraulic punching square notch equipment, hydraulic cutter and folder. The electrical control system uses a computer with a closed-loop and servo-system to increase the precision and reliability of the manufacture line. The maximum working speed is 16m/min.The length tolerance is±0.3mm. The diagonal line tolerance is ±0.5mm. One team will produce 1000㎡of square duct by using this system.Hot Tags : HVAC duct fabrication machine line Duct fabrication machine line HVAC duct machine Air duct forming machine Ventilation duct machine Hvac machines

Read More -

Asymmetric 3-Roller Plate Bender

The 3-roller bending machine features the diamond structure and is used for thicker sheets. The upper roller can be lifted to facilitate plate removal.It is cut into two kinds:symmetric and asymmetric.Hot Tags : Asysmmetric 3-roller bender Bending machine 3 roller plate beading machine HVAC bender Metal plate bender Symmetric sheet metal bender

Read More -

Decoiler and Leveler Line

The uncoiling and leveling production line is used for various roll bending processes. After uncoiling, leveling, and cutting, flat sheets of the required width and length can be obtained. The production line consists of a feeding rack, uncoiler, leveler, conveyor, guide device, length fixing device, plastic cover plate device, shearer, and conveyor table.Read More

IPv6 network supported

IPv6 network supported