TDF Fire Damper Frame Production Line

Fire damper machine consists of frame production line,positive pressure air supply outlet production line,blades forming machine,supporting bar forming machine,spring forming machine,riveting platform and so on.

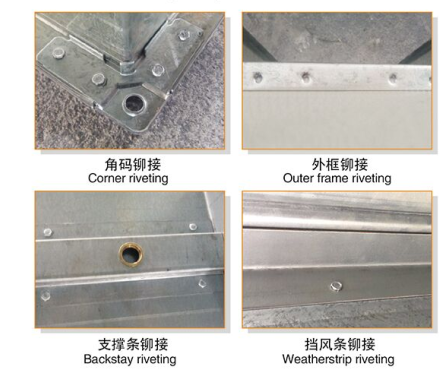

Finished products of rivets platform:

Description of function:

The riveting platform of fire valve is composed of outer frame riveting (four riveting), Angle corner (four riveting), supporting bar (double riveting) and wind shield strip (single riveting). Double and single can be configured according to customer requirements (rotating wall hanging, rotating bracket).

Basic Configuration:

|

Model |

Capacity(mm) |

Weight(kg) |

Dimension(mm) |

| LC-MJ | 2+2 | 3500 | 2200x1300x1200x2 |

online service