-

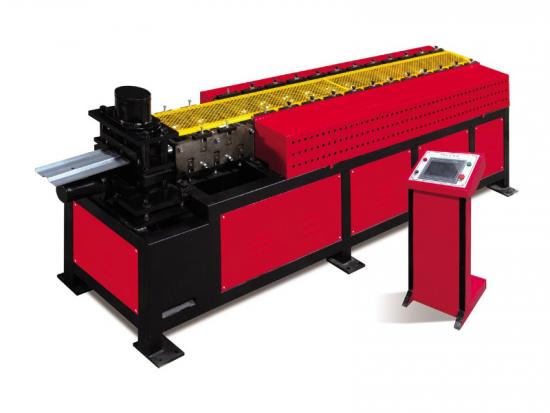

Duct Manufacturing Duct Line V

Ventilation duct machine The air duct production line V is composed of feeding frame, leveling and beading, hydraulic punching point and square mouth, hydraulic shearer, movable pittsburgh forming machine,feeding platform, duplex flange machine, duplex angle iron flange machine (or double snap lock machine), servo feeding platform and TDF hydraulic folding. The computer control part adopts full computer control, bending with servo feeding, accurate positioning, especially when processing the bigger air duct, to ensure the bending accuracy.Hot Tags : Duct equipment Duct fabrication machinery Air duct fabrication machine CNC duct fabrication machine line HVAC duct manufacturing machines line Ventilation duct machine

Read More -

CNC Press Brake

The main function of press brake is for metal processing industry. The products are widely used in light industry, aviation, shipbuilding, metallurgy, instruments, electrical appliances, stainless steel products, steel structure construction and decoration industries. Hydraulic bending machine is the first choice for sheet metal processing of sheet metal, especially for large sheet metal. By selecting and matching different molds, the sheet metal can be bent, stretched, pressed, punched, etc.Hot Tags : Press brake Hydraulic folder Hydraulic folding machine Hydraulic folding machinery

Read More -

TDF Fire Damper Frame Production Line

Fire damper machine consists of frame production line,positive pressure air supply outlet production line,blades forming machine,supporting bar forming machine,spring forming machine,riveting platform and so on.Hot Tags : VCD frame production line VCD frame forming machine Fire damper machinery VCD damper frame roll forming machine

Read More -

Damper Blade Roll Forming Machine

The blade forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : Blade forming machine Blades forming machine VCD damper blade roll forming machine HVAC damper blade rolling forming machine

Read More -

Baffler forming machine for fire damper machine

The baffler forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : VCD machinery Fire damper machines

Read More -

HVAC Damper Spring Leaf Roll Forming Machine

The spring forming machine for fire damper machine adopts PLC control, LCD touch screen, human-computer interface. Realize the interaction between human and Panasonic PLC. The operator can automatically run (programmable control) and monitor the control process through the set program, so as to realize the operator to control the production line and modify the control parameters, and monitor the equipment operation status, operation parameters and fault indication in real time. The length of the work piece can be adjusted.Hot Tags : Spring Forming Machine Spring rolling machine

Read More -

HVAC Damper Rivet Table

Fire damper riveting platform consist of frame riveting(four rivets),TDF corner riveter(four rivets),supporting bar riveting(two rivets) and baffler rivets(single rivet).Hot Tags : Riveting platform Volume control damper machinery Volume control damper machines

Read More -

Duct Manufacturing Auto Line VIII

Air duct production line Ⅷ is a new type of air duct automatic production line of our company. The U-shaped structure not only saves the production site, but also reduces the delivery time of raw materials. The production efficiency is high (about 20-23 seconds per piece). The department fully automatically realizes the fixed size cutting, beading, automatic cutting ,the notching, single hem forming, pittsburgh forming, TDF flange and the angle iron flange ,automatically forming and bent into ”L“, ”U“, ”口“ shaped duct. Equipped with punching support air, TDF flange hole is optional. Pittsburgh is formed before bending the short side of the large size duct. It has the advantages of high automation, high efficiency, labor saving and material saving.Hot Tags : Duct manufacturing auto line Fully-automatic duct making line HVAC duct machinery line Automatic duct line Rectangular duct forming machine HVAC machine

Read More -

Duct Manufacturing Auto Line VII

HVAC duct line Ⅶ ,with U-shaped structure not only saves the production site, but also reduces the delivery time of raw materials. The production efficiency is high (about 20-23 seconds per piece). The department fully automatically realizes the fixed size cutting, beading, automatic cutting ,the notching, single hem folding, pittsburgh forming, TDF flange and the angle iron flange ,automatically forming and bent into ”L“, ”U“, ”口“ shaped duct. Equipped with punching support air, TDF flange hole is optional. Pittsburgh is formed before bending the short side of the large size duct.C+S flange is optional.It has the advantages of high automation, high efficiency, labor saving and material saving.Hot Tags : HVAC machinery line HVAC machinery HVAC auto duct line machine HVAC fabricate duct complete line

Read More

IPv6 network supported

IPv6 network supported