Duct Manufacturing Auto Line Vl

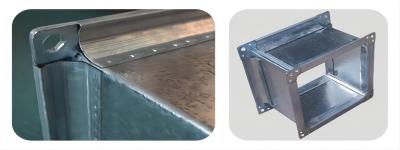

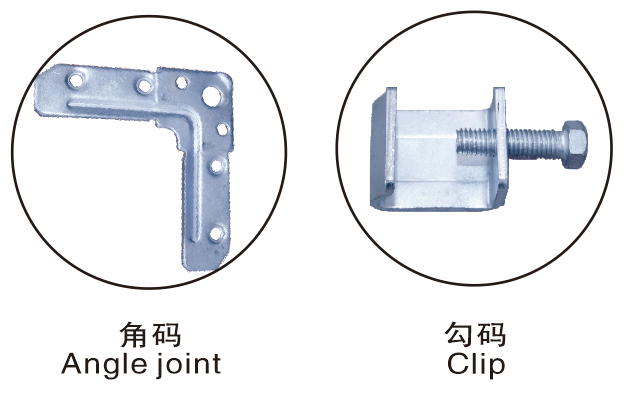

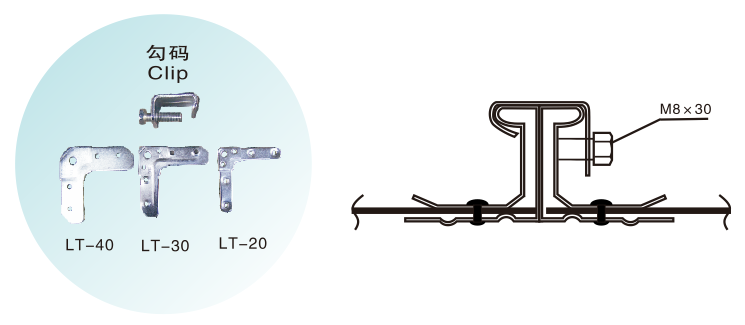

HVAC duct line VI,the U-shaped structure not only saves the production site, but also reduces the delivery time of raw materials. The production efficiency is high (about 20-23 seconds per piece). The department fully automatically realizes the fixed size cutting, beading, automatic cutting ,the notching,pittsburgh forming, TDF flange and the angle iron flange ,automatically forming and bent into ”L“, ”U“, ”口“ shaped duct. Equipped with punching support air, common plate flange hole is optional.It has the advantages of high automation, high efficiency, labor saving and material saving.

IPv6 network supported

IPv6 network supported