TDF Fire Damper Frame Production Line

Fire damper machine consists of frame production line,positive pressure air supply outlet production line,blades forming machine,supporting bar forming machine,spring forming machine,riveting platform and so on.

Fire Damper Forming Machine video:

Finished Products:

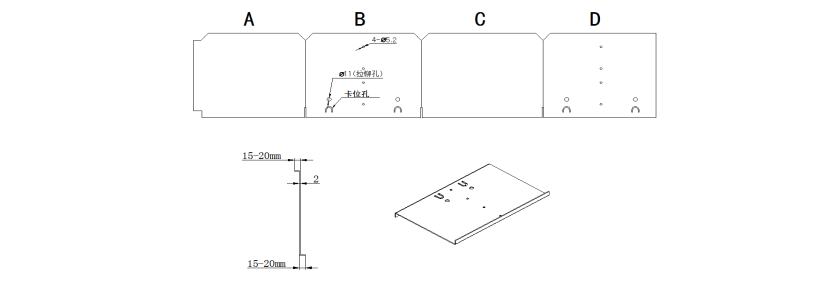

Product drawing:

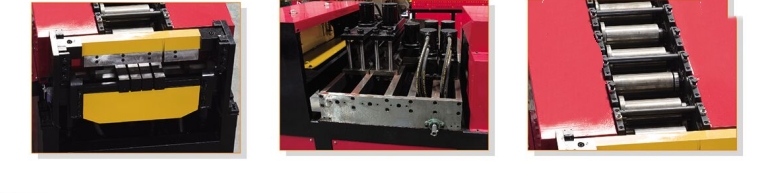

Detail of Machine:

Description of function:

●Double servo motor, fullautomatic operation

●Finished damper frame width:200-320mm

●Flange size:15mm

●Processing mode:Lshape/口shape/sheet

●Output:500pieces frame/8hours

Basic Part:

online service