TDF Fire Damper Frame Production Line

Fire damper machine consists of frame production line,positive pressure air supply outlet production line,blades forming machine,supporting bar forming machine,spring forming machine,riveting platform and so on.

Electrical control system of supporting forming machine:

PLC: Panasonic of fpx-c30t

True color touch screen: Taiwan Winon

Detection encoder: Japan internal secret control encoder

Servo drive system: Viktor (or invetion) servo drive system

Low voltage electrical appliances: circuit breakers and contactors are domestic famous brand "Chint" electrical appliances, and relays are "Omron" or "Schneider".

Damper Supporting Bar Roll Forming Machine:

Damper Supporting Bar Roll Forming Machine video:

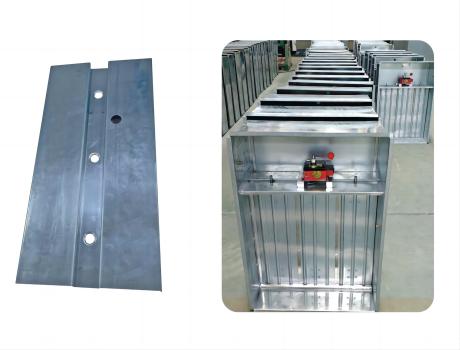

Finished Products:

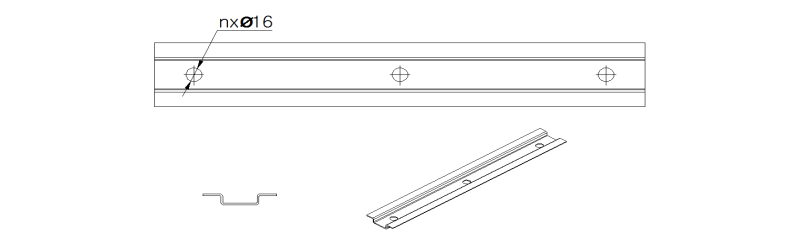

Product drawing:

Description of function:

●It can be shared with the septum forming machine

|

Model |

Thickness range(mm) |

Width(mm) |

Max-working speed(m/min) |

Coiler weight(kg) |

Weight(kg) |

Motor(kw) |

Dimension(mm) |

| LC-ZG | 1.5-2 | 120/210 | 10 | 2000 | 5000 | 12 | 5000x800x1300 |

online service