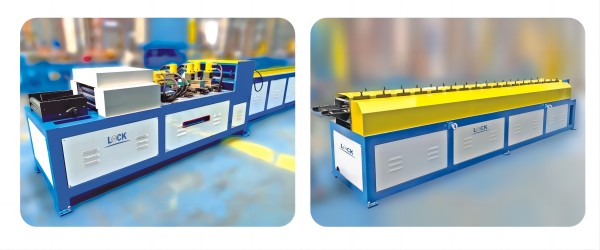

Fire Damper Forming Machine

Positive pressure air supply molding machine is composed of uncoiler, cold rolling molding machine, straightening, shaping, cutting with fixed length, punching and manual discharging.

The full-automatic fire damper produced by LOCK. is ahigh-efficiency full-automatic productionline

Fire Damper Machine video:

Professional Fire Damper machine manufacturer-LOCK:

Fire Damper Frame Forming Machine Video:

Fire Damper Frame workshop:

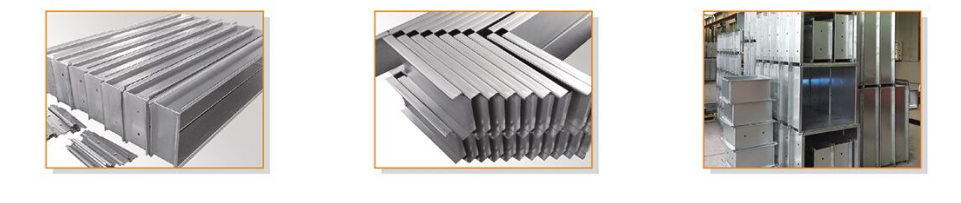

Finished Products of VCD frame:

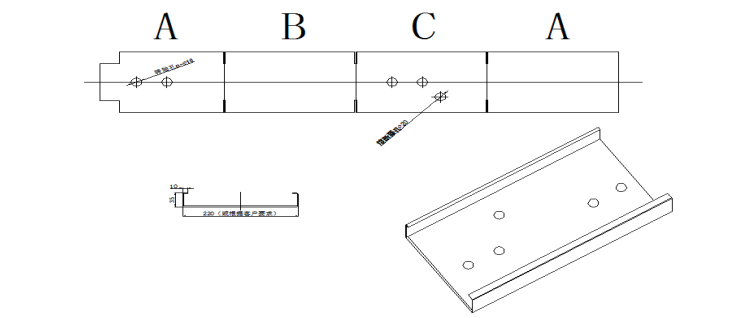

Products drawing:

Description of function:

●Double servo driving,full automation operation

●Finished damper frame width:200-250mm

●Flange type:35TDFfange(with 30 Angle Steel function)

●Processing mode:Lshape/口shape/sheet

●Output:500pieces frame/8hours

●Meet 3C standard

Device detail:

1.Motor decoiler one set

4.Punching on-off installation hole die one set

5.Punching blade installation hole die one set

6.Hydraulic Cuting device one set

7.Feeding platfor one set

8.Main rollforming machine one set

9.Hydraulic bending device one set

10.PLC one set

online service