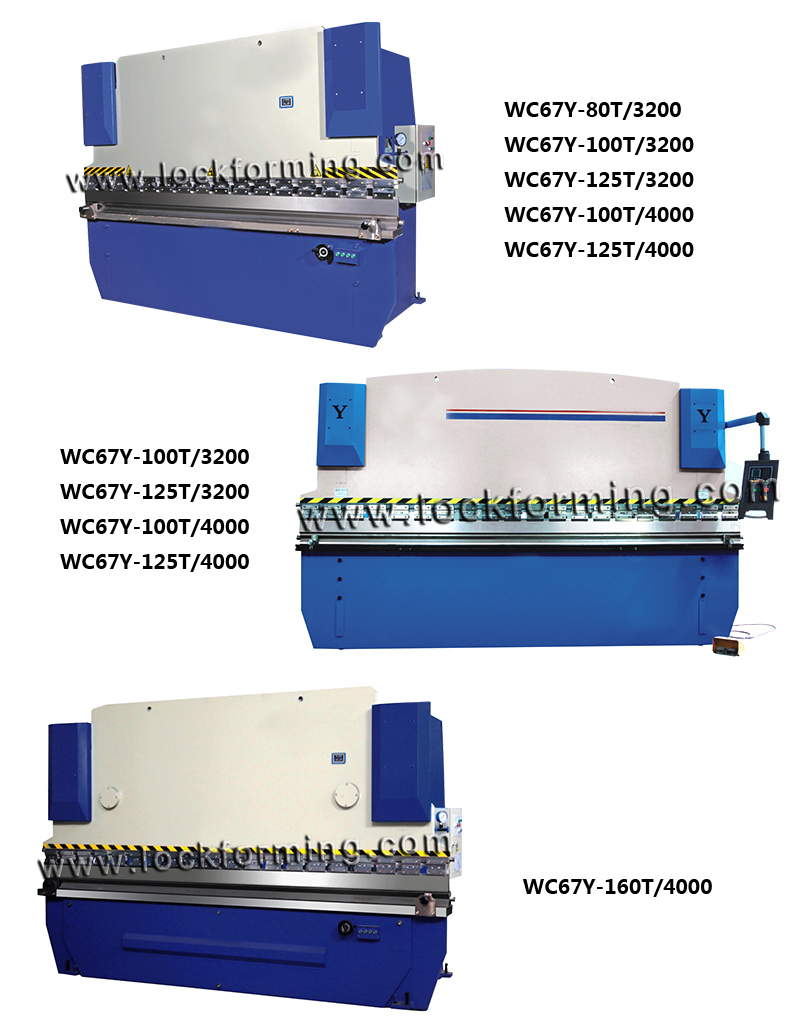

CNC hydraulic press brake

The main function of press brake is for metal processing industry. The products are widely used in light industry, aviation, shipbuilding, metallurgy, instruments, electrical appliances, stainless steel products, steel structure construction and decoration industries. Hydraulic bending machine is the first choice for sheet metal processing of sheet metal, especially for large sheet metal. By selecting and matching different molds, the sheet metal can be bent, stretched, pressed, punched, etc.

IPv6 network supported

IPv6 network supported