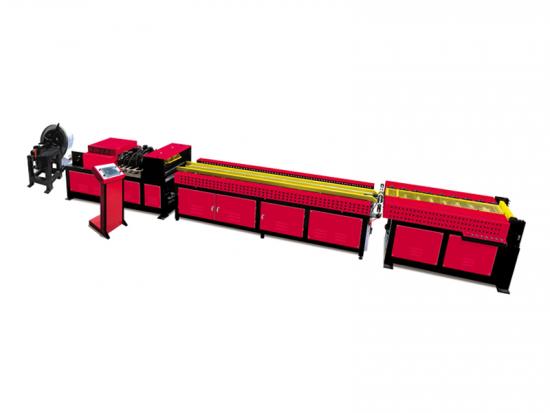

The positive pressure air outlet valve body forming production line consists of decoiler, leveling, hydraulic

shearing,punching square mouth,punching sharp corner, punching round hole, valve body forming machine, olding

machine and hydraulic shearing. It adopts full computer PLC control and touch screen operation, and can b

any size according to the operation requirements.The pressure air supply frame is fully automatic production, which

greatly improves the production efficiency and is suitable for use in fire damper prduction plants.

Electrical control system of Positive Pressure Air Supply outlet Production Line:

PLC: Panasonic of fpx-c30t

True color touch screen: Taiwan Winon

Detection encoder: Japan internal secret control encoder

Servo drive system: Viktor (or invetion) servo drive system

Low voltage electrical appliances: circuit breakers and contactors are domestic famous brand "Chint" electrical appliances, and relays are "Omron" or "Schneider".

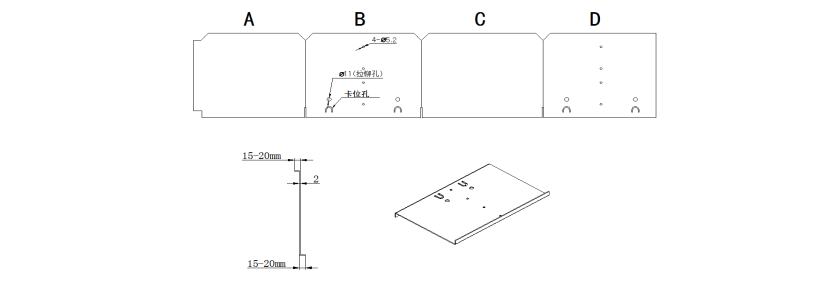

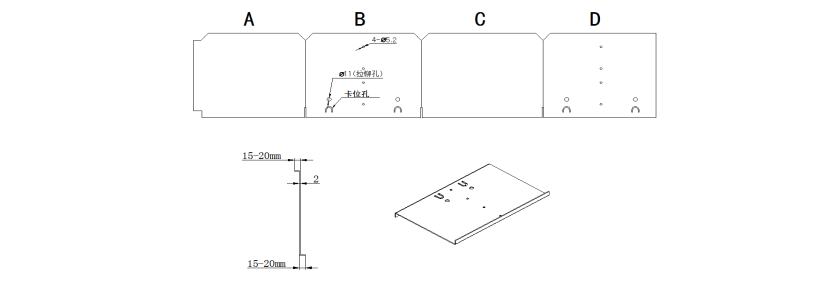

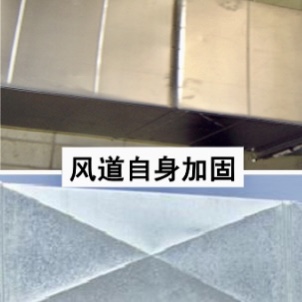

Finished Products:

Product drawing:

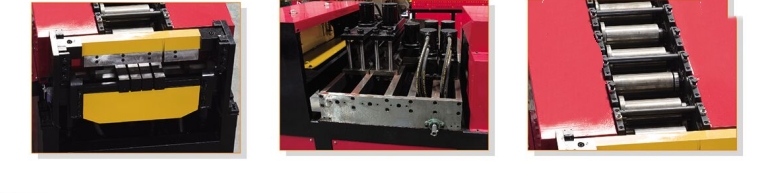

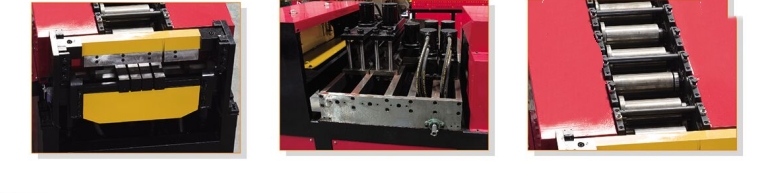

Detail of Machine:

Description of function:

●Double servo motor, fullautomatic operation

●Finished damper frame width:200-320mm

●Flange size:15mm

●Processing mode:Lshape/口shape/sheet

●Output:500pieces frame/8hours

●Meet 3C standard

Basic Part:

●Motor decoiler one set

●Leveling device one set

●Two sets of square and sharp notching dies

●Punching on-off installation hole die one set

●Punching blade installation hoe die one set

●Hydraulic shearing divice one set

●Feeding platform one set

●External frameforming machine one set

●Hydraulic folding device one set

●CNC operating system one set

|

Model

|

Thickness range(mm)

|

Width(mm)

|

Max-working speed(m/min

|

Coiler weigth(kg)

|

Weight(kg)

|

Motor(kw)

|

Dimension(mm)

|

|

LC-ZY

|

1.2-2

|

220/270

|

10

|

3000

|

80000

|

22

|

10000x1000x1300

|

IPv6 network supported

IPv6 network supported